Coffee Table Part 1 – Construction Begins!

I have been working on a Mahogany coffee table. This commission started like all of the rest, with a visit to the clients house. I then retreated to my studio to pour over my measurements and begin to design the table. Before too long I was well organized so I went ahead and built a model. Now things began to feel a bit off. It wasn’t the design, it was the scale that seemed off. The clients immediately confirmed my suspicions and commented that the table seemed big. A few days later I brought a cardboard cut out of the giant table to the clients house. Loosing the proportions ended up providing an opportunity to have a dialog with the clients as I cut the cardboard down to size. I enjoyed the process and the clients found it helpful so it will now become a standard part of my presentation! A nice discovery.

Here we go. The rough Mahogany boards that will form the table top.

They then get chopped to the rough size.

Off to the jointer to flatten one side of the boards. It takes two passes per board to get them perfectly flat.

Next stop is the Planer. The newly flattened side faces down and rides on the precision table. The cutter-head makes the top face as flat and parallel to the jointed face.

The processed lumber goes back together and the model comes out for reference.

I want each board in the table top to have a wedge shape. This is an integral part of the design so I mark each board and head off to the bandsaw to rough cut the shapes

Here is the fan shape. I have run the edges over the Jointer so they are perfectly flat and ready to glue together

I will break the table top up into a number of different glue-ups. This will give me an opportunity to shape and detail the table as it evolves.

I coat each joint with aliphatic resin glue AKA Yellow woodworking glue.

Then the joint gets clamped together. Even pressure will close the joint that was prepared earlier on the Jointer.

Coffee Table Commission

Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

Part 7

Part 8

Part 9

Part 10

By Nico Yektai -

By Nico Yektai -New York based designer/maker Nico Yektai opened the doors to his Hamptons studio in 1995 after completing the MFA program at the School For American Craft at the Rochester Institute of Technology. The rigorous technical training complimented his background in Art History, which he studied, at Hobart College in Geneva NY. Yektai has synthesized this background into a singular style that has gained him national attention. Visit nicoyektai.com for more information

Corner Piece #3 – Part 2

Often reality sets in when it is least welcome. I had to move the newly cast base and it proved to be just a bit too heavy. It has to have a certain weight to provide a stable foundation but no question it was too heavy.

The solution is a bunch of foam

A bit of steel

These parts were carefully positioned and will cut the weight by a fair amount. It is the difference between being able to easily move the casting vs. struggling. (I should note that i have superhuman strength so it is still quite heavy to the average person)

Note: The silvery Stainless Steel parts are threaded inserts that get locked into the concrete and will be used to fasten the wood.

THe piece is beginning to take shape!

The holes correspond tot he threaded inserts that i buried in the casting.

The ash components are designed to hide the screws that hold the cherry to the concrete. Even if there were no holes to cover I would still want the ash pieces. They increase the footprint and provide the visual “glue” to tie the concrete and the Cherry components together.

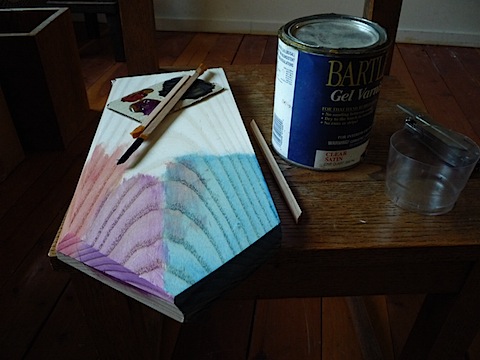

The Ash is providing too much of a contrast so it will need some help. I sneak across the street to steal some Oil paint from my father. (One of the many advantages of having an Artist for a father)

A few samples later I decide on a mix of Indigo and Ivory black to mellow the Ash and help it tie into the concrete.

Finished!

Detail.

Corner Piece #3

Part 1

Part 2

By Nico Yektai -

By Nico Yektai -New York based designer/maker Nico Yektai opened the doors to his Hamptons studio in 1995 after completing the MFA program at the School For American Craft at the Rochester Institute of Technology. The rigorous technical training complimented his background in Art History, which he studied, at Hobart College in Geneva NY. Yektai has synthesized this background into a singular style that has gained him national attention. Visit nicoyektai.com for more information

Corner Piece #3 – Part 1

I have always wanted to build a corner piece with a concrete core. Here are the two that I have previously made.

I had to be careful to provide a large enough footprint so that they would be stable. While I was building them I was thinking about concrete and the fact that the weight would help the stability of the piece. I now have the concrete skills to pull it off so I decided to jump in with a model.

There is no client involved so the model is a bit rough, almost like a 3D sketch.

This piece centers around the concrete so that I where I will begin. The concrete elements in my work are cast. This means that I will have to think inside out. The form material is a special plywood that is waterproof and has a smooth coating. I refer to it as “Red Board”

Here is the finished form.

Note: this component is cast upside down.

Now I will show the individual pieces that make it up. I need to stay one step ahead as the cast concrete can lock itself into a poorly designed form and require the destruction of the form to get it out. Yes I have made that mistake!

The back of the form

The front of the form

There is also a separate piece for the top (not pictured). All of the parts are caulked in place so that they will be water tight. I should mention that I use UHMW plastic to make the facets for the corners. I use the facts to relate the concrete to the rest of my work. Plus I can change them to give the casting a different look.

The concrete mix and the extra materials to give it a bit more strength go into the mixer.

The form gets loaded and agitated to encourage the bubbles to work their way out.

Three days later I free it from the form.

It was a successful pour!

To be continued…

Corner Piece #3

Part 1

Part 2

By Nico Yektai -

By Nico Yektai -New York based designer/maker Nico Yektai opened the doors to his Hamptons studio in 1995 after completing the MFA program at the School For American Craft at the Rochester Institute of Technology. The rigorous technical training complimented his background in Art History, which he studied, at Hobart College in Geneva NY. Yektai has synthesized this background into a singular style that has gained him national attention. Visit nicoyektai.com for more information