Desk #2- Part 1

I have been thinking about new work for the Architectural Digest Home Design Show in NYC and the Smithsonian Craft Show in D.C.. The need for new work seems to have converged with a bit of success one of my pieces has had in the blogosphere. I recently added Desk #1 to my website. I made this piece while I was a student and it marks the moment that my style had matured. The piece is still one of the best that I have made and someone at the Russian design blog Novate agreed. Well, I think they agreed! Please do not shatter my fragile ego if this translates to something less than flattering.

Occasionally a blog post will go a bit viral. This one traveled through a number of translations into half a dozen languages before it ended up in English again. This digital success encouraged me to do something that i have alway wanted to do- revisit this piece. In the coming blog posts I will chronicle the process of designing and building a piece like this.

My goal is to pick up where I left off with the desk and see if I can push new ground. The first principal that will be different is the two tiered approach to the curved elements in this desk. The original had a three layer system. The model below helped me get organized and then…

I was able to pull the actual curves down from the shelf and mock it up. Purchasing and inventorying these steam bent curves was one of the best things I have done for my workflow! Once I had the curves where i wanted them I was able to cut plywood blocks to help me figure out the angles that I would need to cut on the legs. You may notice that the curve on the left is quite thick. I will need to trim it down before I go any farther.

I take the piece over to my big saw, the Tannewitz, and peel off a useable chunk. I love that saw!

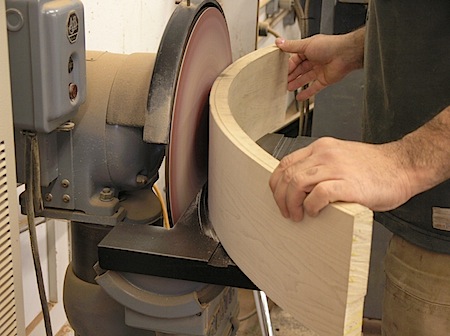

A quick trip to my State disk sander to clean up the bandsaw marks and I am back to figuring out the joinery.

I mentioned these pieces before. They will show me the profile that the legs will need to have to give the desk it’s shape.

Here they are lined up agains the end of the 3″ thick maple board. You can see that my approach to woodworking is very efficient! I will be able to get the maximum yield from this piece of wood.

The legs start their transformation from this huge plank at the chop saw station. Then it is back to the trusty Tanny to rough the legs out. I used the plywood template from the previous shot to set the angle of the table.

I take the legs over to the Oliver Jointer to clean up one side of each leg.

Next in the chain is the planer. I will clean up the side of the board parallel to the one that I just did on the jointer

I get some more mileage out of those plywood pieces. I use one to set the angle on the table saw.

Now they see their final action. I set the angle on the small jointer to clean up the remaining rough surfaces on the legs.

I have replaced the plywood place holders with the actual legs.

As of now everything is right where I want it. I am ready to lay out and execute the joinery. It is going to be quite involved so I will leave it for the next post.

Two New Tables With Glass

The new hall table has quickly evolved from the model stage to near completion good thing since the Architectural Digest Home Show is coming right up. This often happens when the miniature has clarified the major design considerations. I knew that this was going to be an interesting piece and more importantly I knew exactly what needed to be done. All of the head scratching was out of the way, thanks to the model building process. I will add a photo with the clamps off so you can get a feel for the process of going from model to real piece. The structure is faithful to the scale version but all of the detailing came to life in the full scale version.

The glass is on order and I am feeling inspired so I set out to make an accompanying piece. As I think about the upcoming shows that I will be participating in I realized that I would like to have a new pedestal table. I often use them as studies for new techniques and explorations. I am feeling like it is time to introduce something personal to the glass that is incorporated into my work.

Up to this point I have worked with glass in its most basic form- the rectangle. My furniture is capable of incorporating a stock material like this. Everything around that conventional piece of glass pushes, pulls and shifts away from convention. The natural evolution of this type of development is that I get to the point where I am comfortable with the new material and I can begin to push it from its expected form. This is the exact same process that I went through when I introduced concrete into my work. I cautiously incorporated it and then I began to allow it a greater role in the composition. Now I am ready to start the process with glass surfaces.

A pedestal table will serve me well for this experiment.

This time I am flying without a model so there will be a start and stop cadence to this one. The table is clamped to my workbench as I figure out the structure and the joinery. I am using steam bent curves from my inventory. I have an inventory of steam bent maple curves that I purchased from a company that specializes in making these parts.

The last curve is clamped in place to get a feel for the final form of the table. Now I need to figure out the glass top. This piece would suffer with a rectangular piece of glass – all I know is that the table needs a unique shape for the top.

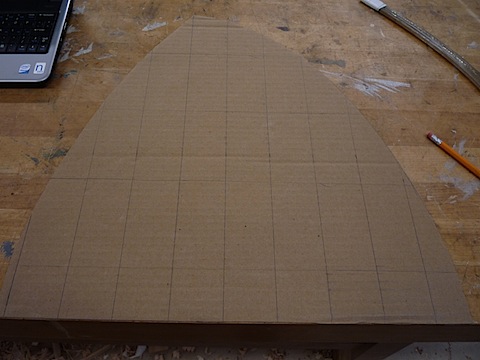

Cardboard and scissors are my choice to work out the shape. I work it out so the glass hugs the shape of the dynamic under structure and it also adds dynamoc movement to the composition.

Now is where I panic – How much is this piece of glass going to cost?

I shift gears and make a drawing so I can get a quote. I create a grid on the template and then I draw it on my laptop and email it to my glass supplier.

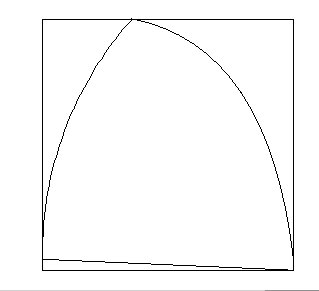

Here is the drawing I sent them. The outer square is for reference only but it nicely shows the movement of the glass top. The silence of the glass supplier means that they may not have received my email or it could mean that this is ghoing to be cost prohibitive… my fingers are crossed.

Regardless of the glass snafu I press on with the table.

Before I left for the day I was able to shape and assemble one more leg. Today I will loosely assemble the third leg and work out the third curve. I seem to insist on not taking all of the pictures I need so I will be adding another post shortly.