Mirror With Two Drawers – Veneer

I always like to present a broad range of work when I have an opportunity to show my furniture. I have two shows coming up. ACC Baltimore and the Architectural Digest Home Show in NYC. Both shows would benefit from a slender wall mounted mirror. I got out the hot melt glue gun and started to design the piece. It quickly evolved to the point where I had enough designed to know that the Mirror and drawer combination was going to make for a compelling composition.

This is the 3-D sketch of the new Mirror with two drawers. This sketch represents the bare minimum that is needed to get started. Lots of choices remain to be made during the construction of the piece. The implication of this type of construction is that I have to build the piece. This immediately establishes that my work is about more than just the functional result. It is about the exploration of one person. I digress – this is a glimpse of the ongoing conversation in my head about “Art Furniture” Perhaps someday I will dedicate a post to trying to further sort out these ideas.

I am going to focus on the fabrication of the two drawers and their carcasses (the box that a drawer goes into). I wen to my veneer shelf and pulled out this ‘Unknown B’ veneer. I purchased it years ago at an auction that benefited WARP. The veneer was 30+ years old when I purchased it and the species of wood had long been forgotten.

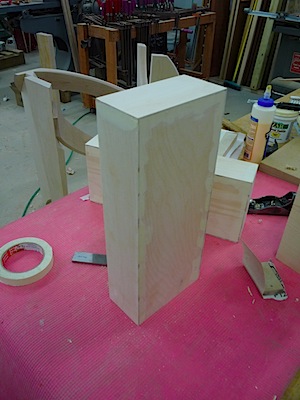

I quickly make two plywood boxes that i intend on wrapping with this veneer.

Cutting the veneer is facilitated by the use of a specialized saw. It a hybrid device part saw and part knife. It allows me to cut the delicate veneer without destroying it.

The edges of the veneer are cleaned up via the jointer. I clamp a number of these sheets together and treat them like a single piece of solid wood. The jointer makes them all perfectly flat at the same time.

The next step is to pull the joint together with masking tape. It stretches just enough to provide just a bit of clamping pressure tot he joint to bring it home. Next the sheet gets flipped over and a special veneer tape seals and reinforces the joints. The tape is water activated. It shrinks just a bit as it dries. The veneer tape is now holding the joints closed. I flip the sheet and remove the masking tape.

The veneer is glued to the carcass one pair of sides at a time.

The excess is trimmed off with the help of a router bit with a top bearing.

The boxes are now wrapped in veneer!

Once the glue is fully cured (about 24 hours for yellow glue) I use water to re moisten the veneer tape. A scraper blade helps to remove it. Now they are ready to be sanded.

I break out my sample box of veneer as I clean up for the day. The satin wood samples jump out at me as a possibility.

Not a perfect match but possible. I think I will continue to refer to it with the name it had when I purchased it… “Unknown B”

Here is what I love about veneer.

By Nico Yektai -

By Nico Yektai -New York based designer/maker Nico Yektai opened the doors to his Hamptons studio in 1995 after completing the MFA program at the School For American Craft at the Rochester Institute of Technology. The rigorous technical training complimented his background in Art History, which he studied, at Hobart College in Geneva NY. Yektai has synthesized this background into a singular style that has gained him national attention. Visit nicoyektai.com for more information